DISCO's Technology for

High-precision Glass Processing

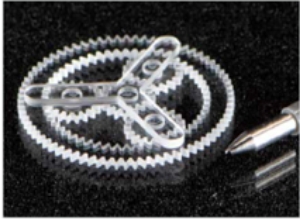

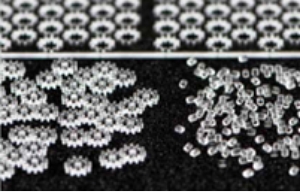

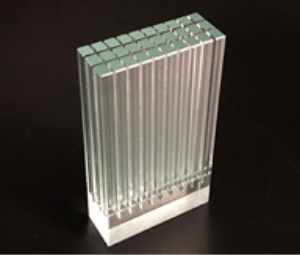

Processing Gallery

Processing methods

DISCO's glass processing

DISCO's precision processing technology has evolved over the years through processing a great variety of materials.

Among these, demand for glass has been increasing in recent years in the semiconductor market for applications such as cover glass for image sensors and glass support substrates for packaging substrates, and the difficulty with regard to processing is also increasing.

The knowhow that we have accumulated by aiming for the best possible processing of materials that can be classified as glass such as quartz glass, alkali-free glass, and borosilicate glass, has become our strength in solving further challenges in the field.

Contact DISCO for any Kiru, Kezuru, Migaku applications related to glass.

What is glass?

Rather than a single definition, there is an extremely large number of categories, and if differentiated depending on the chemical composition, application, and manufacturing method, they can be classified even further.

Almost all glass is made up mainly of Si (silicon) and O (oxygen). Glass is not crystalline, where Si and O are lined up systematically. Since the glass atoms all face in random directions, it is called non-crystalline, or amorphous. Based on this, glass is classified as "a liquid with an extremely high viscosity," but the discussion is still ongoing.

Glass processing

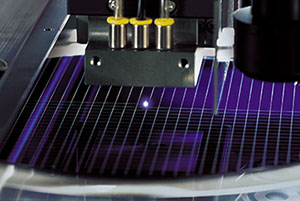

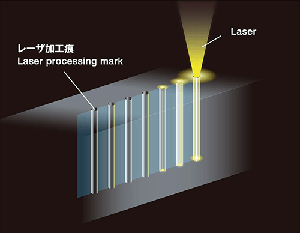

Generally, as glass is a brittle material, chipping tends to occur during processing. At DISCO, by performing non-contact processing using a blade or laser that uses thermosetting resin, we can achieve high-quality processing results for various glass materials.